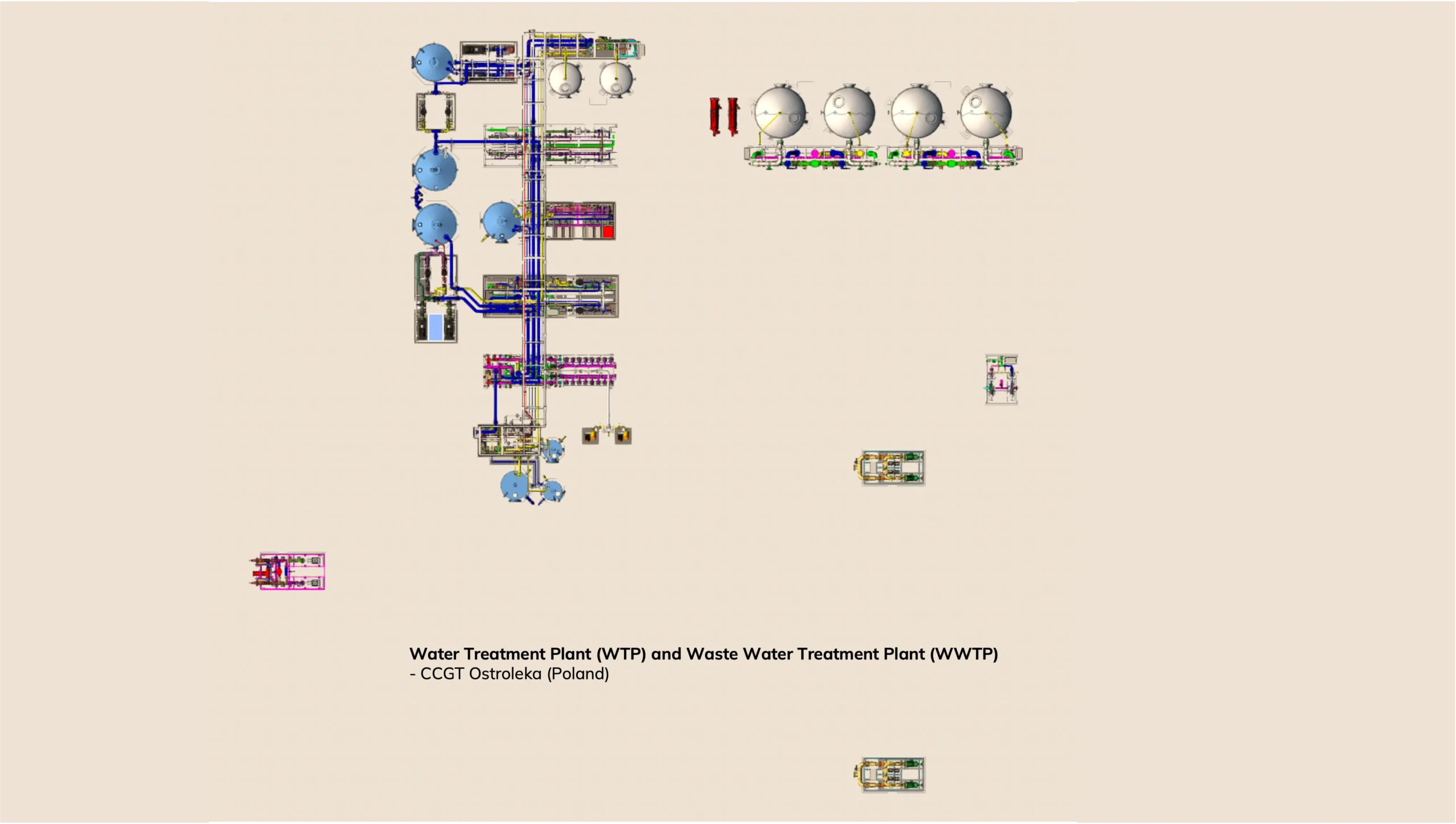

Ostroleka CCGT Water Treatment Plants

Two plants inside one.

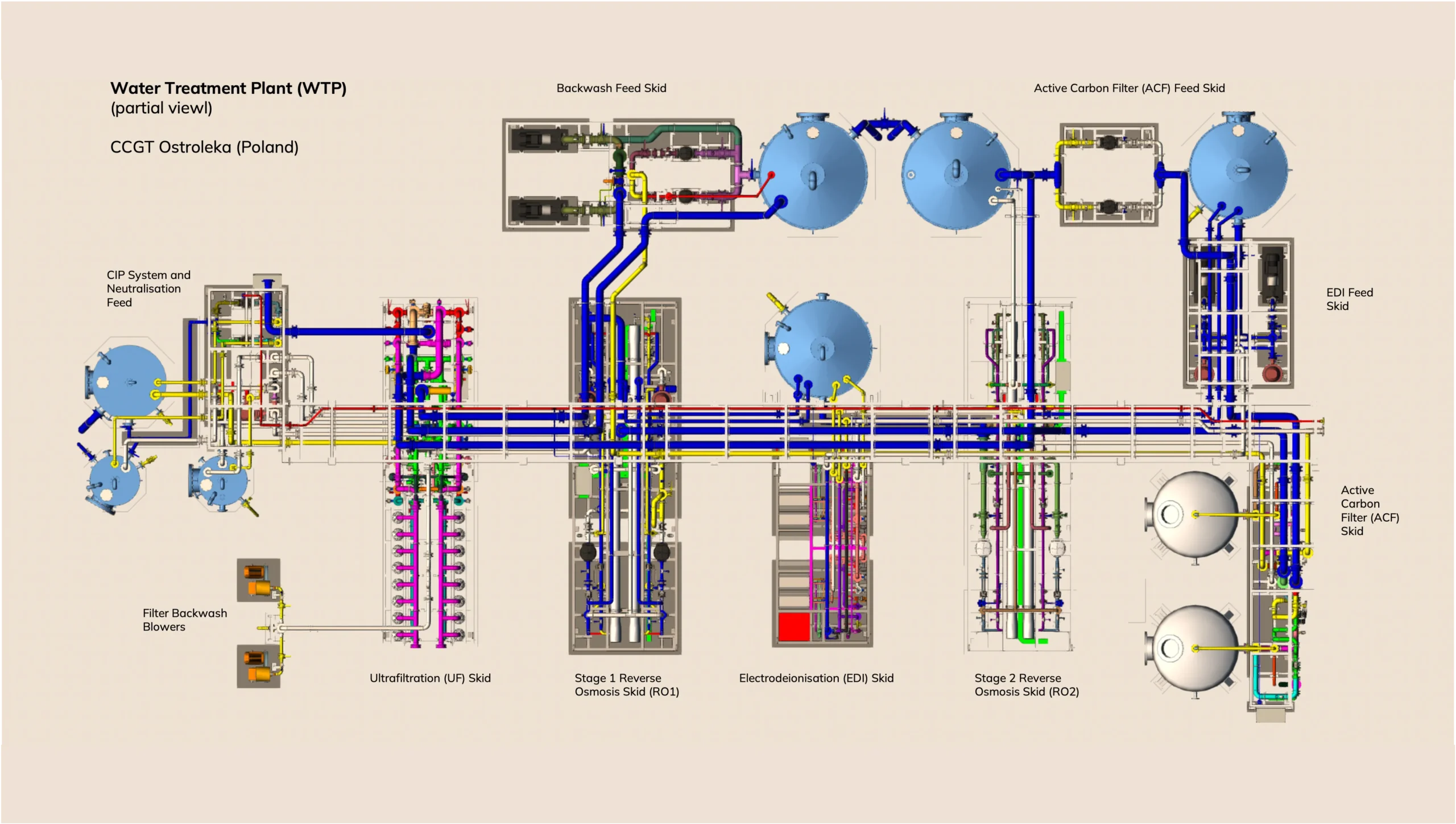

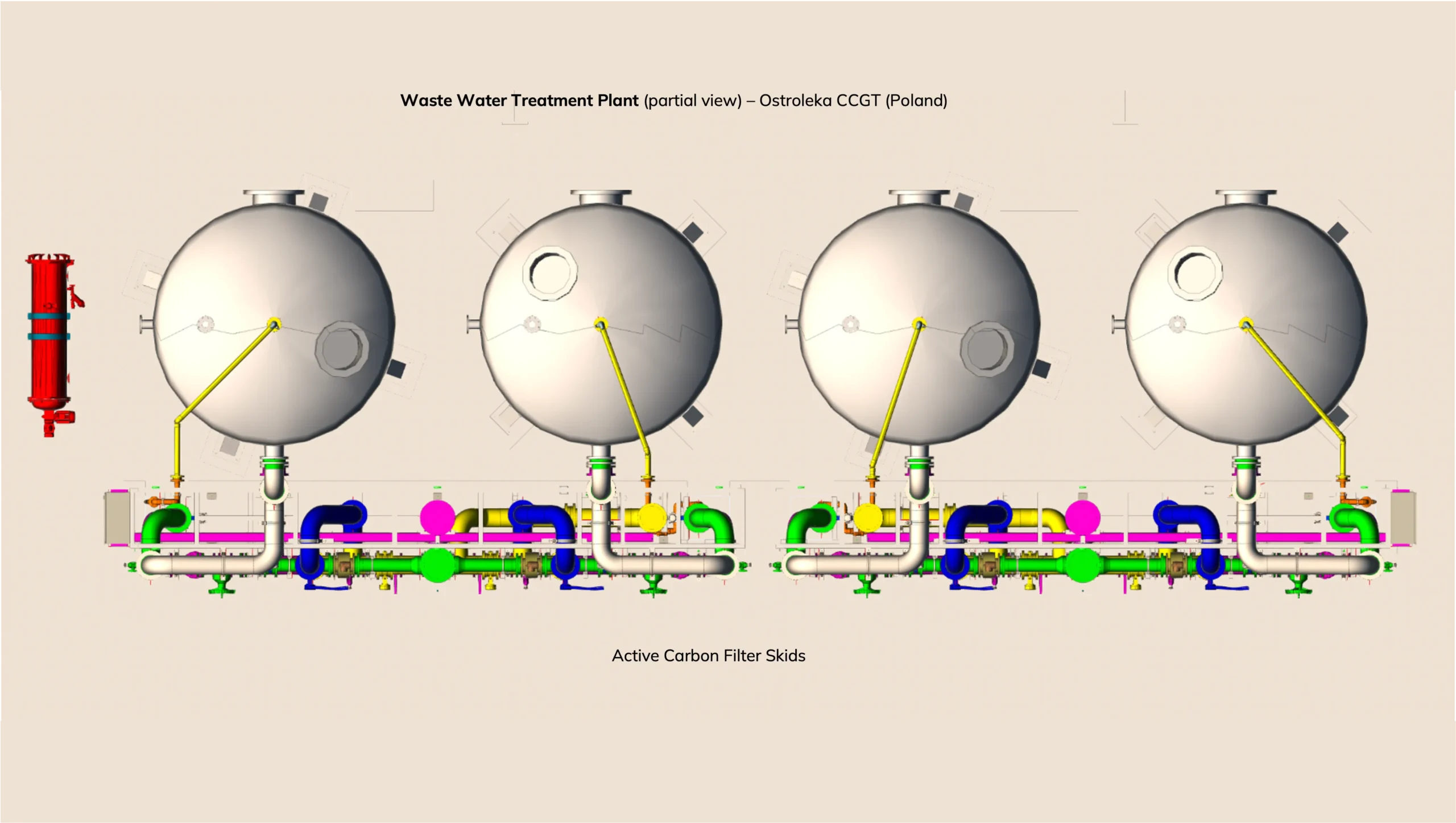

Our work, delivered to PH Technology, has been to complete the full detailed engineering for both the Water Treatment Plant (WTP) as well as for the Waste Water Treatment Plant (WWTP) that service the CCGT, using a 3D BIM model created by Agnua at its core.

With an estimated investment of $642 M and a power output of 745 MW, Ostroleka CCGT has a dual purpose: to bolster Poland’s power generation, diminishing the risk of a power deficit in its National Energy System after 2025, and contributing to achieve the country’s de-carbonisation goals.

It’s construction started in 2022 and operation is expected to begin in 2025.

$M investm

Drone view.

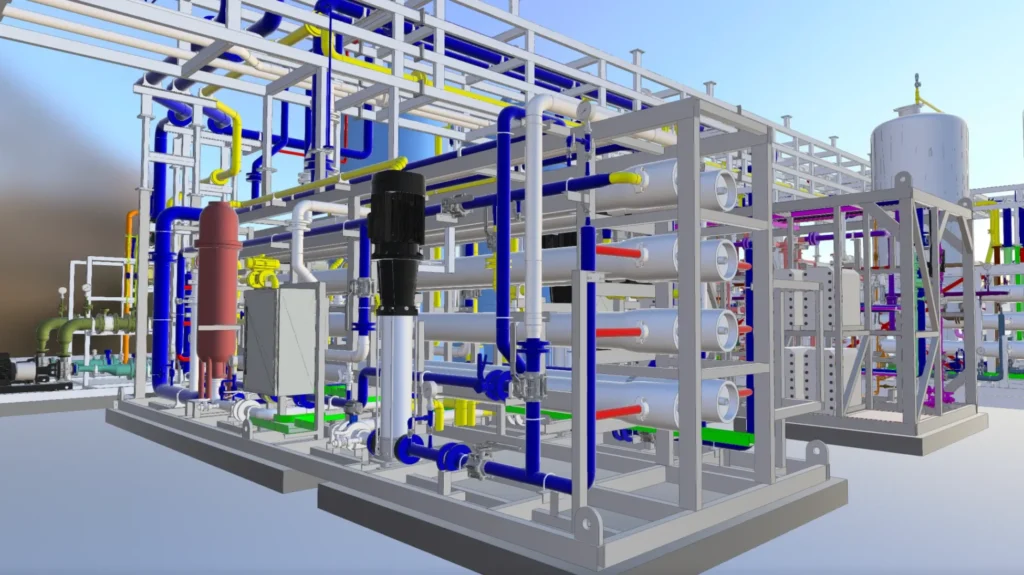

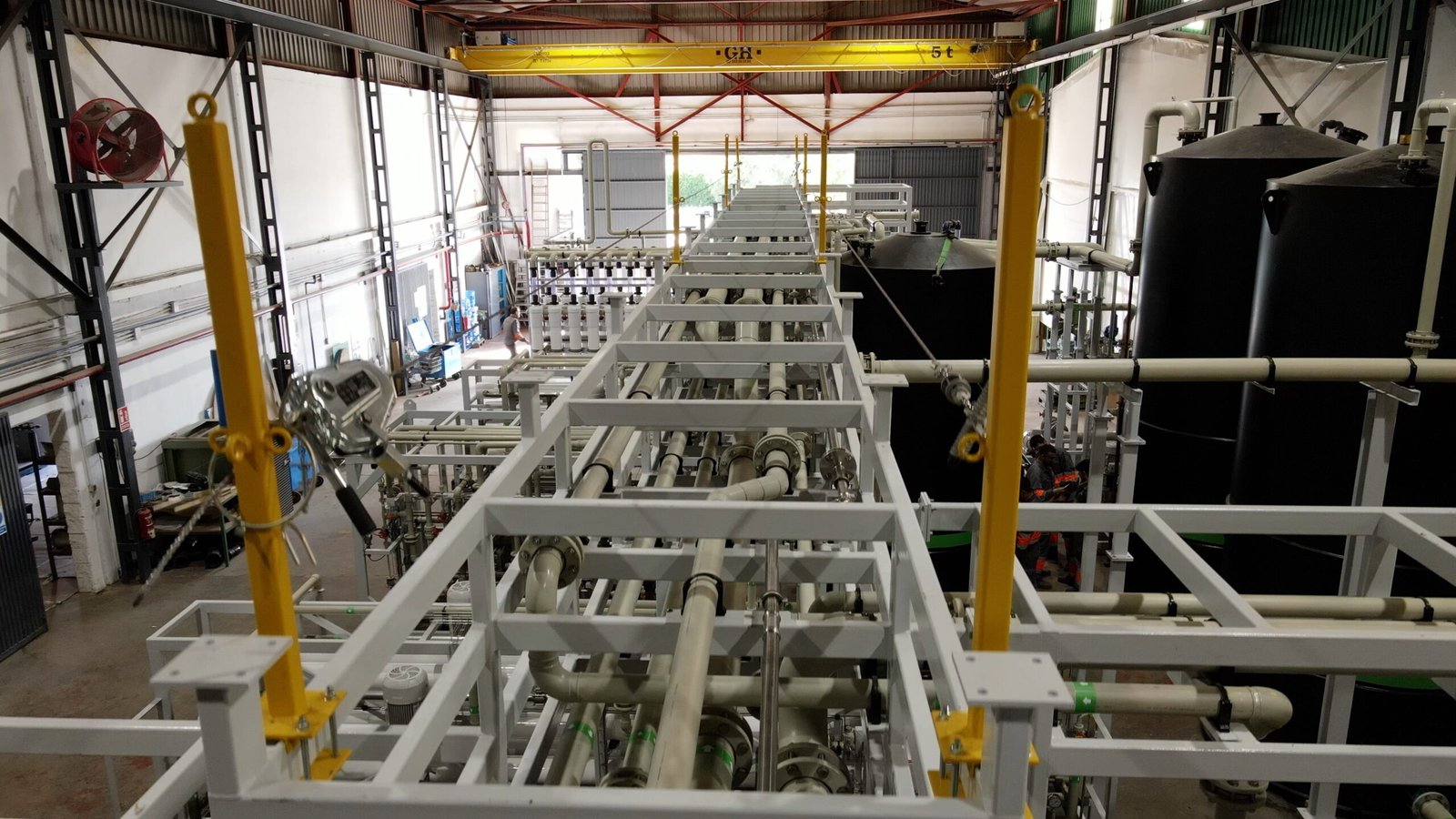

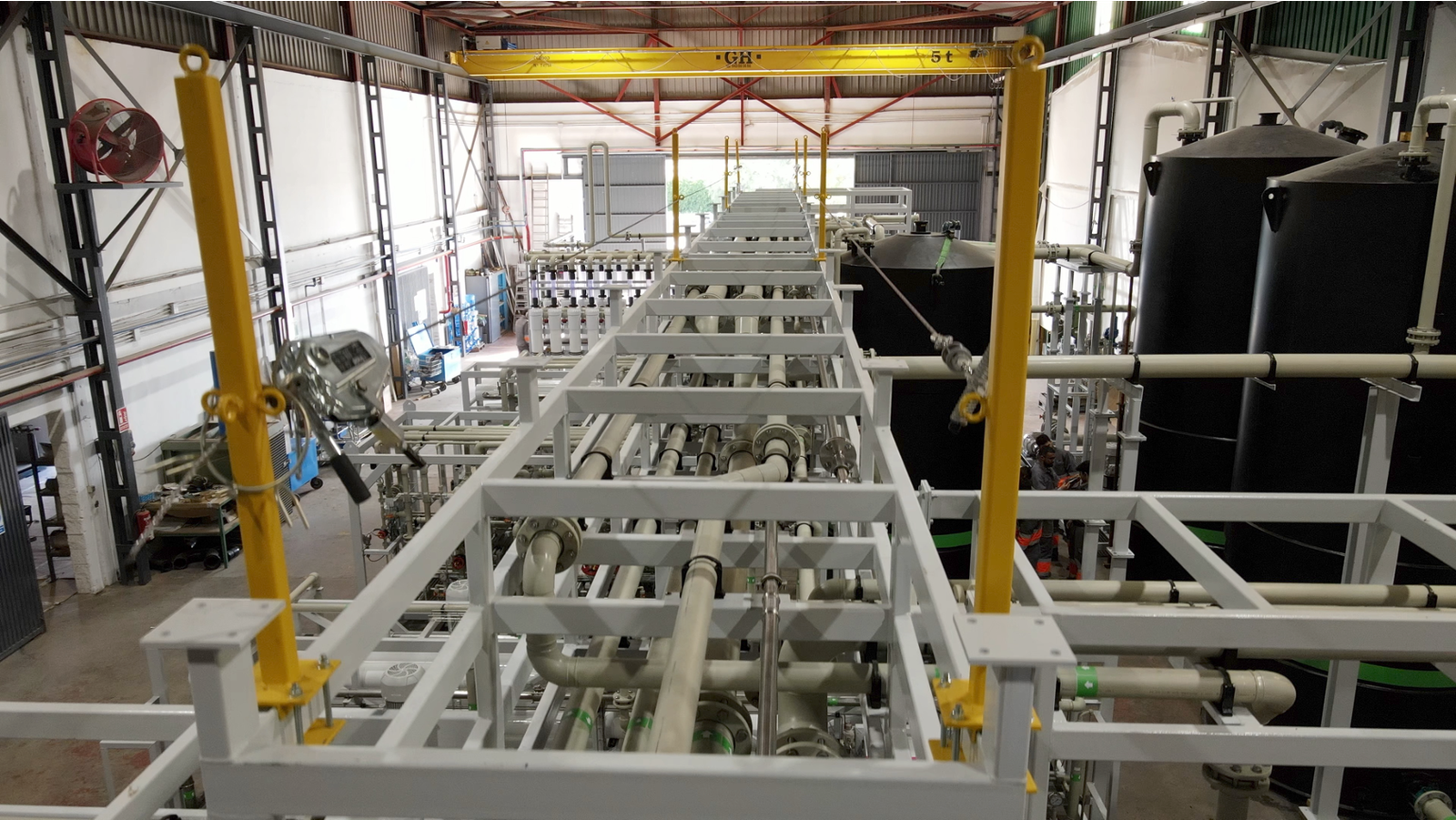

Ostroleka CCGT Water Treatment Plants have been designed and built in modules. PH Technology completed a full installation inside their Huelva factory in Spain, in order to perform extensive testing before their final transport and assembly at their final destination in Poland.

The drone’s view video shows a parcial view of the Water Treatment Plants during their build up and testing phase at Huelva.

Video courtesy of PH Technology

From Design to Manufacturing

Before-After

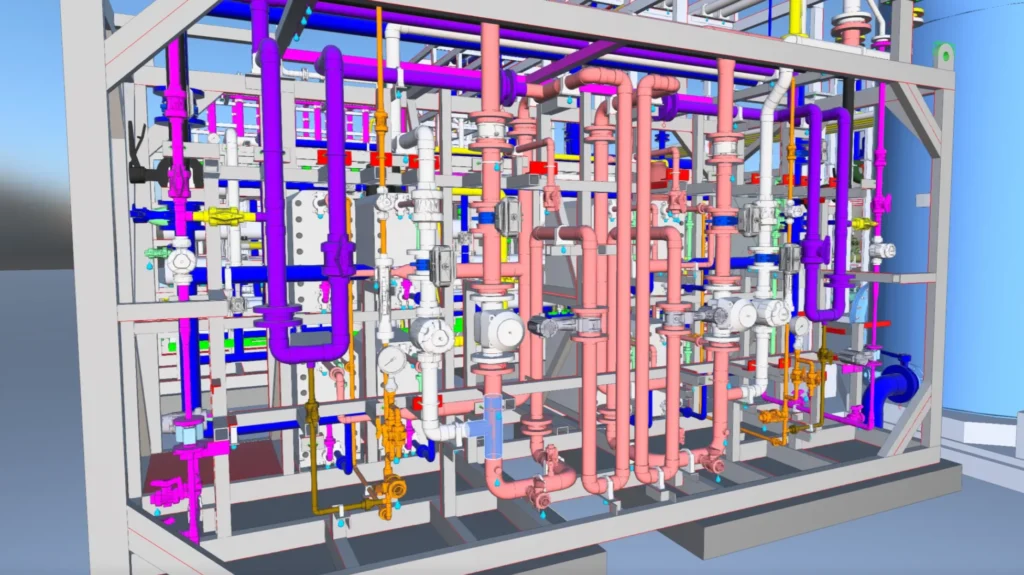

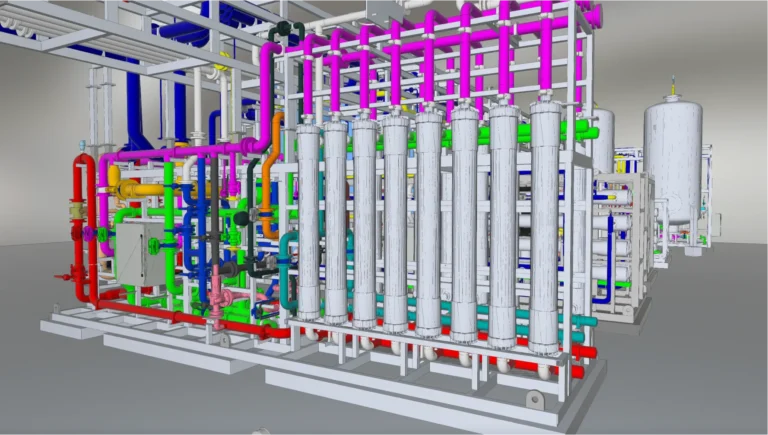

Precision Engineering

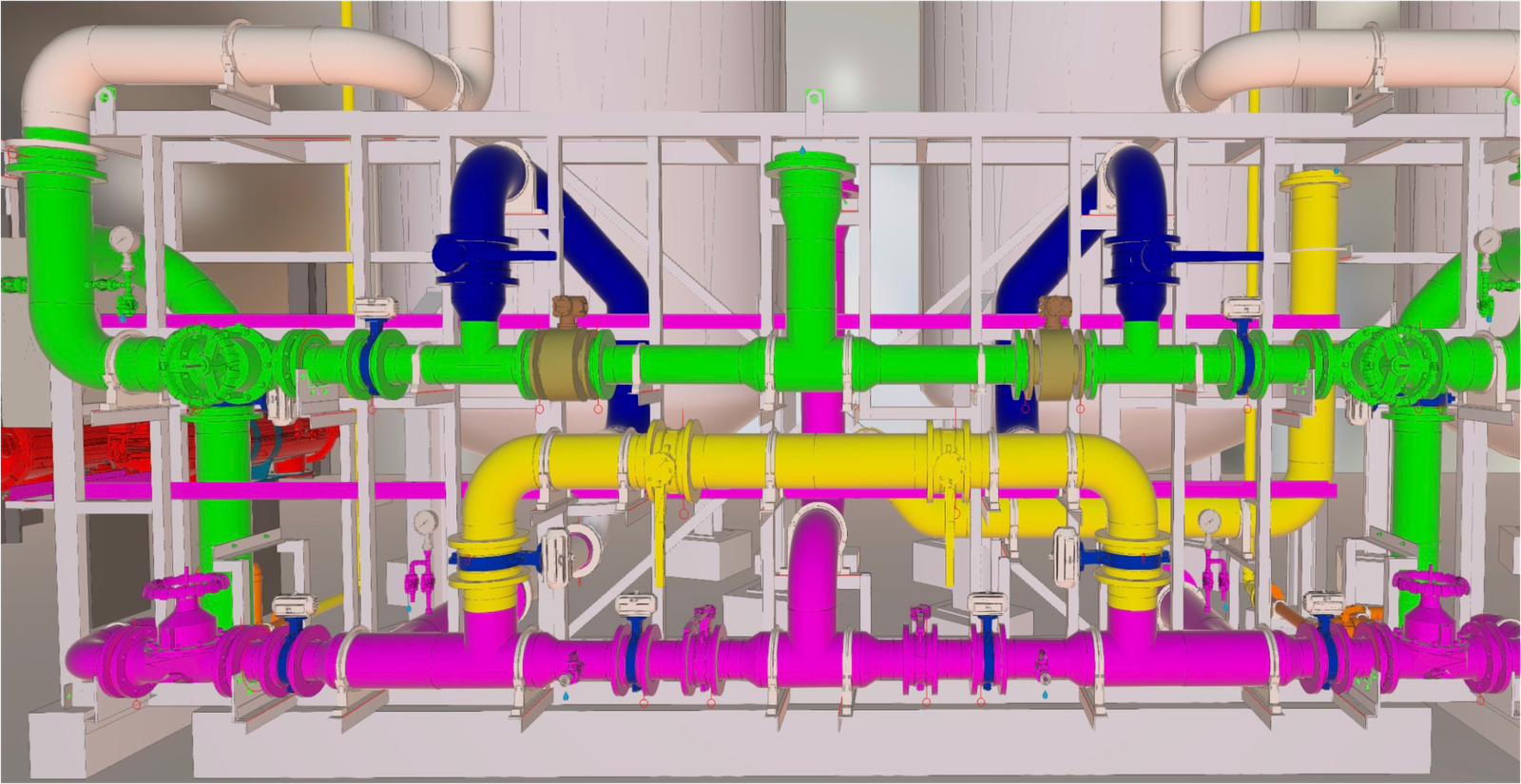

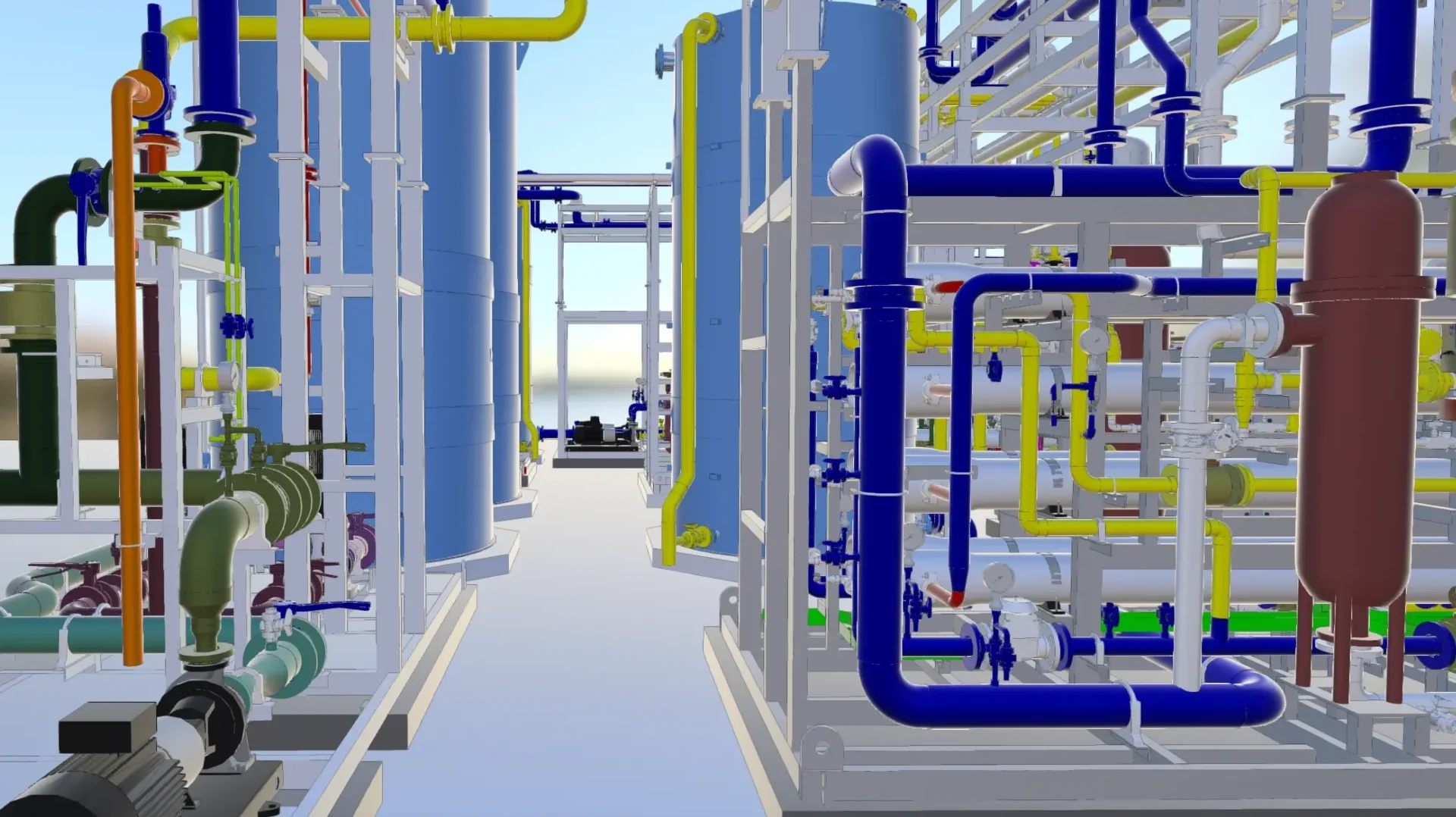

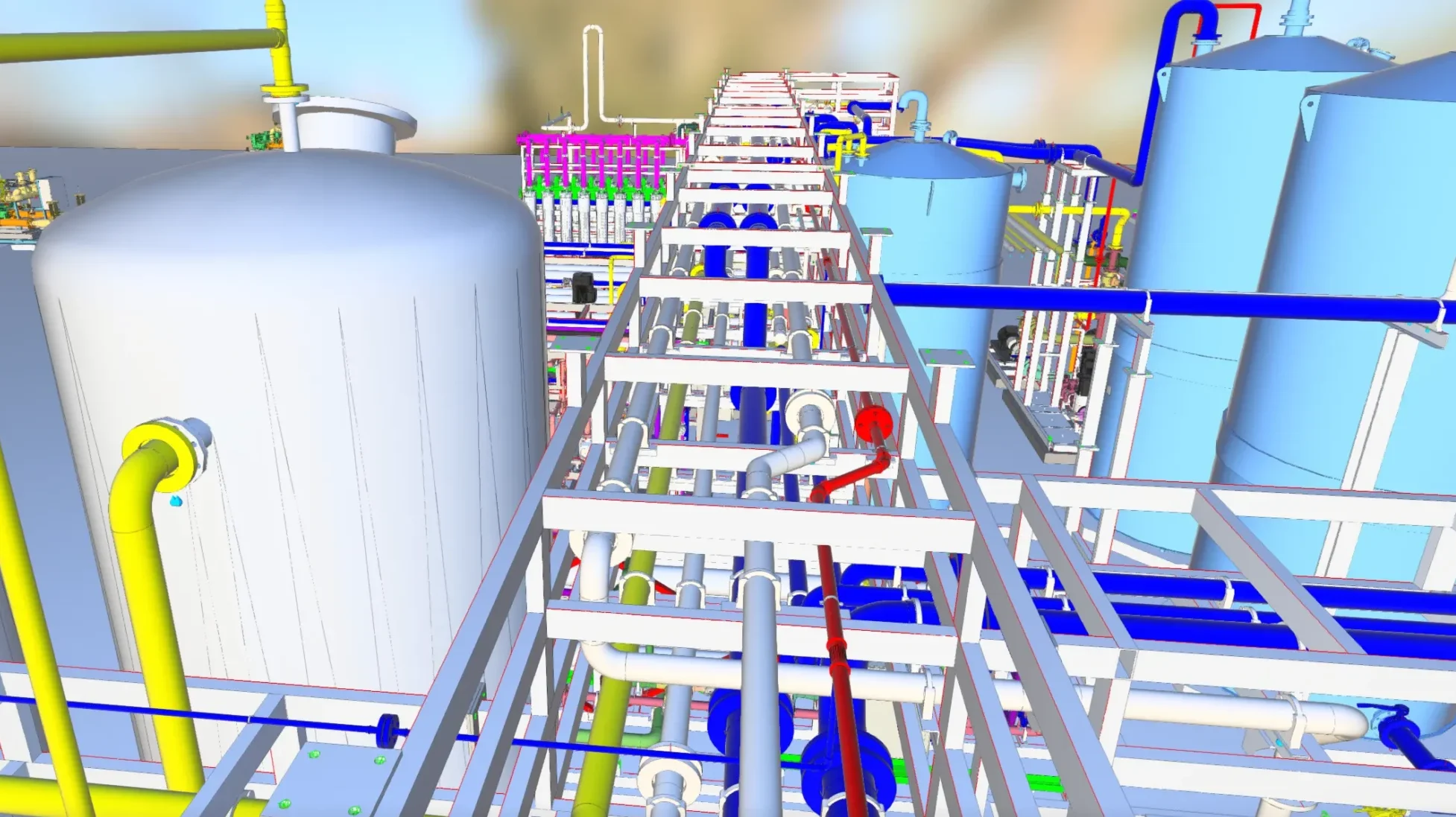

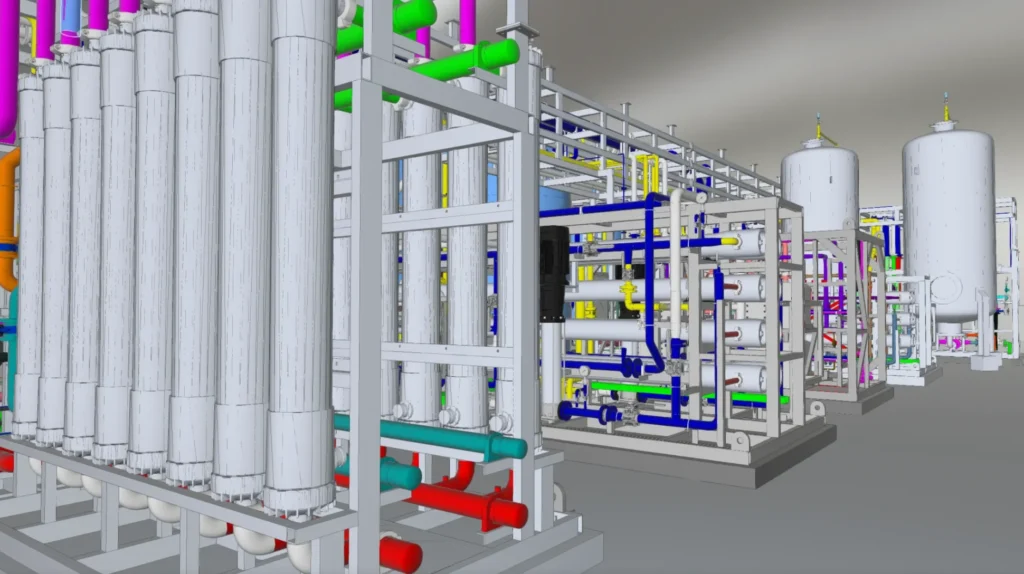

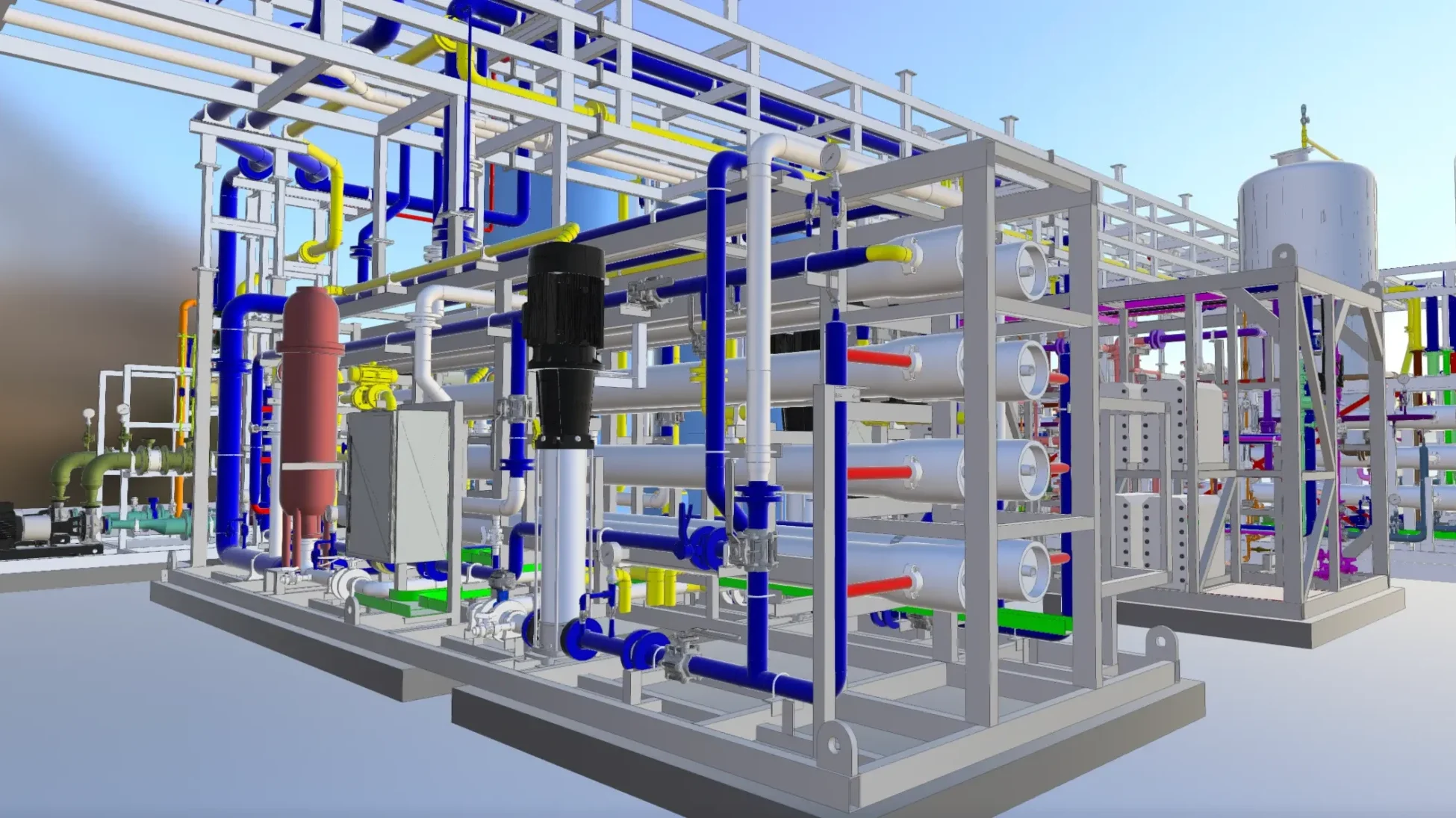

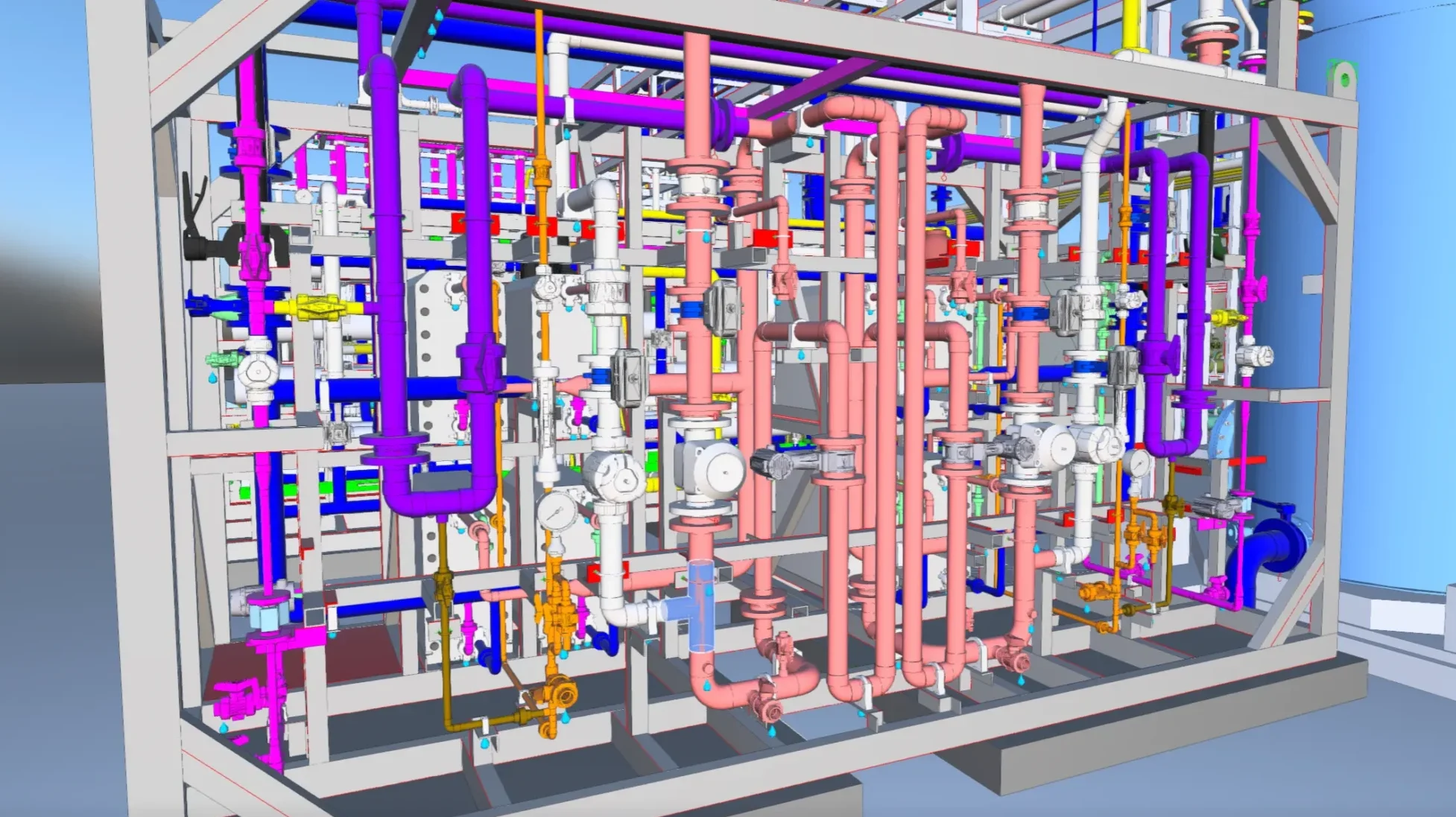

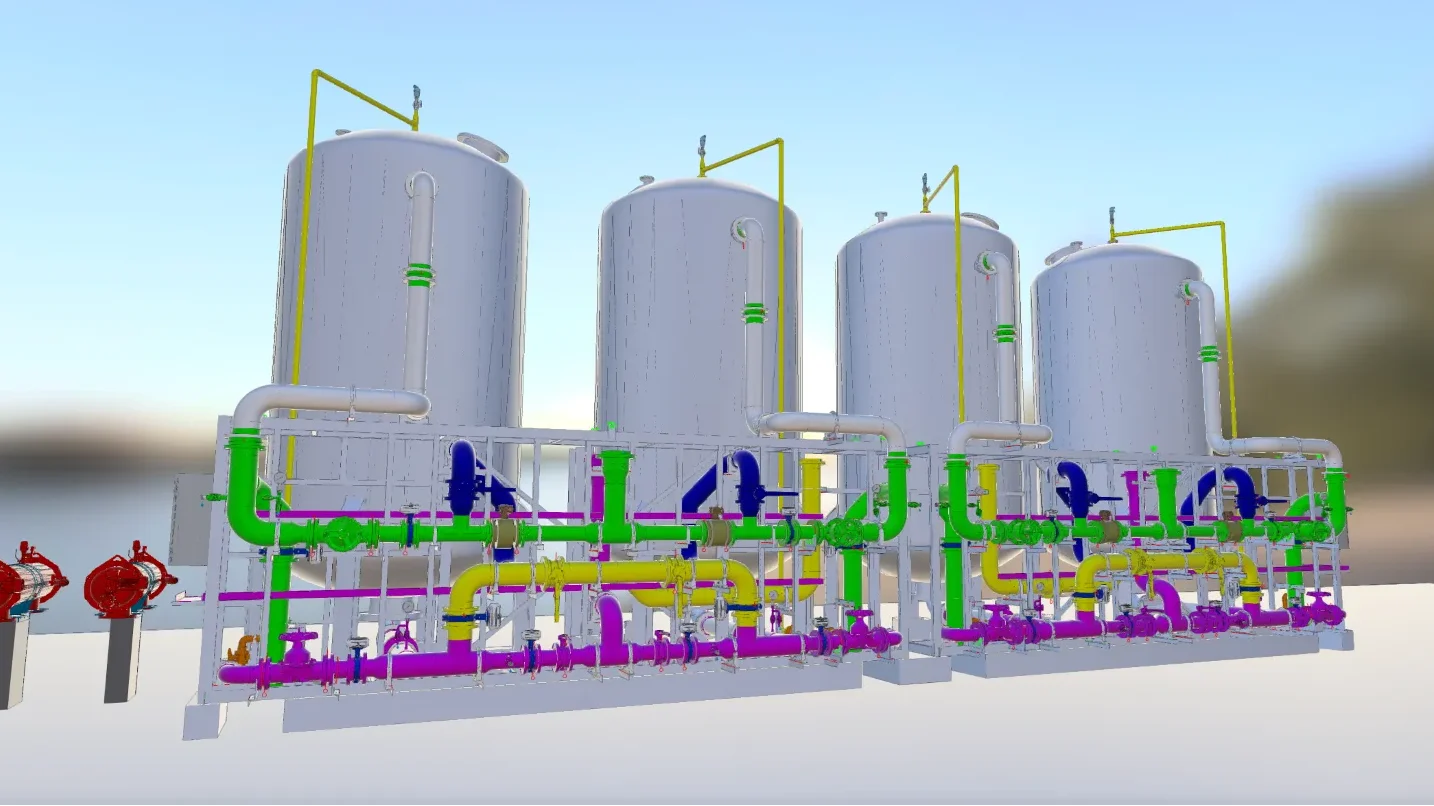

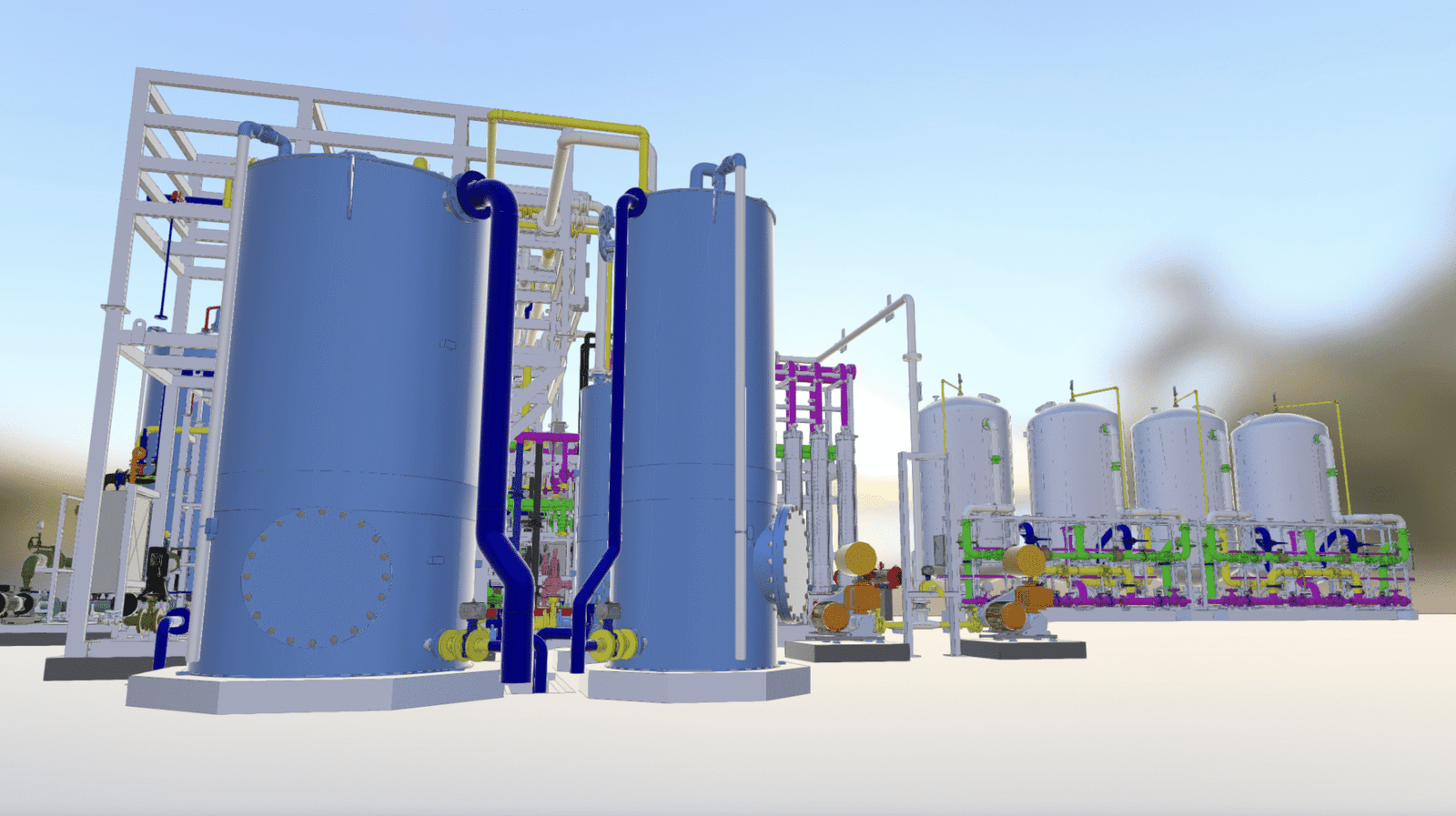

We show a comparative of parts of our 3D BIM Model against real images of the plant, manufactured from it by our client.

They reflect our commitment to representing the plant as accurately as possible, to facilitate its manufacture and assembly, and ensure its proper construction.

Active Carbon Filter (ACF) Skid

EDI Feed, Active Carbon Filter (ACF) and 2nd Stage Reverse Osmosis Skids

How do we help speed up execution times?

One of the particular challenges of Ostroleka’s engineering design arose from PH Technology’s decision to manufacture and install a complete water treatment plant at its Huelva facility, subjecting it to extensive operational testing before its final move to Poland.

To achieve this, we gave top priority to accelerating and anticipating delivery times.

With access to the 3D BIM model in real time

Giving all participating teams real-time access to the plant’s 3D BIM model from day one has allowed each team to begin their respective tasks without delay, fostering close and efficient collaboration and optimizing execution times.

The use of a single, smart digital model of the plant as a central reference source for design and specifications has also enabled rapid adaptation to daily changes.

Smart 3D BIM Model

¿Smart Design?

Fully updated digital libraries

Our 3D BIM digital model is comprehensive, detailed, and smart. It incorporates the technical specifications for 100% of the piping, supports, instrumentation, and the rest of components, via digital libraries created and updated by Agnua. This allows us to provide taables, lists, and factory drawings, contributing to the efficiency and error-free nature of purchasing and manufacturing tasks. If any component changes during the design process, the 3D BIM model automatically adapts to it, for all to follow.

Sample component specifications in the Ostroleka Water Treatment Plant’s digital libraries

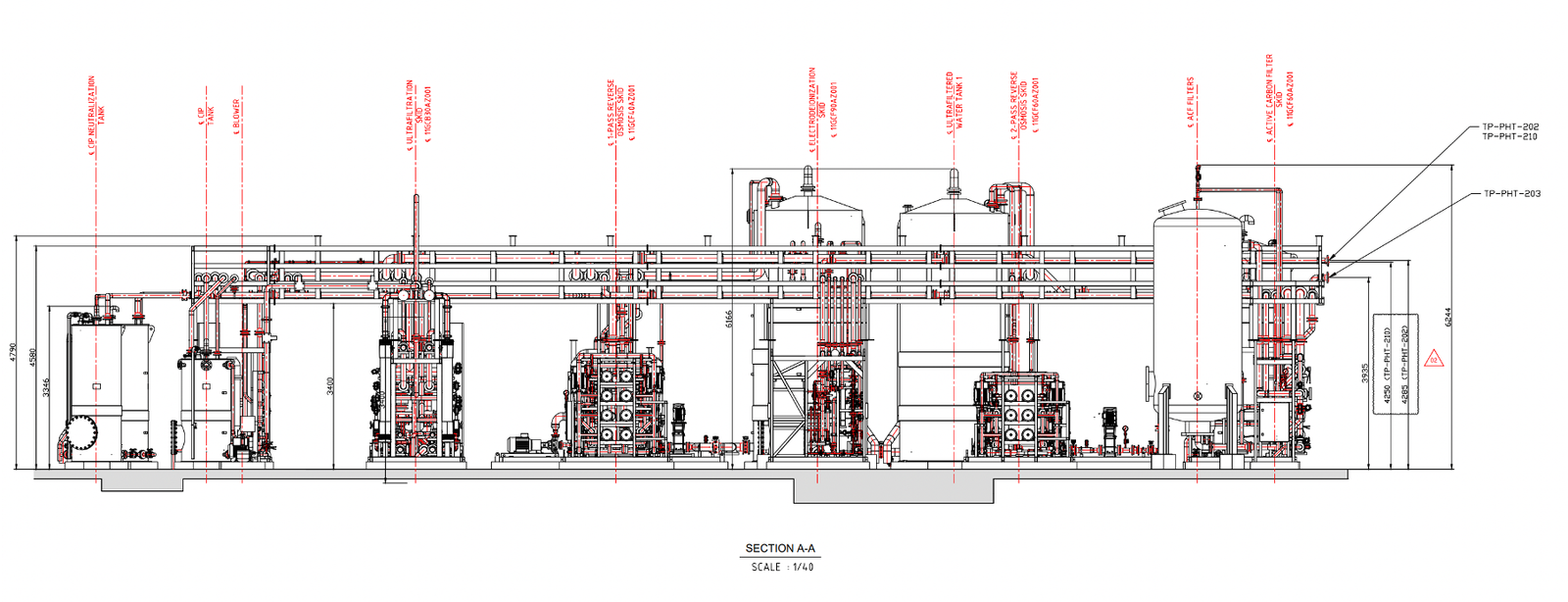

Detailed Engineering completed

Below are the details of the specific work and deliverables carried out by Agnua for both the Water Treatment Plant (WTP) and the Wastewater Treatment Plant (WWTP) at the Ostroleka CCGT.

3D BIM design and modeling of all systems involved

- Ultrafiltration Feed Skid

- Ultrafiltration Skid

- Active Carbon Filter (ACF) Feed Skid

- Active Carbon Filter (ACF) Skid

- Reverse Osmosis Stage 1 Skid

- Stage 2 Feed Skid

- Reverse Osmosis Stage 2 Skid

- EDI Feed Skid

- EDI Skid

- Backwash Feed Skid

- Active Carbon Filters Feed Cleaning Skid

- CIP Tank and Skid

- Ultrafiltration and Neutralisation Feed Skid

- Civil Works

- Interconnecting Piping – Pipe Supports and Racks

Skids manufacturing blueprints

- Steel structure fabrication drawings

- Piping and equipment assembly drawings

- Material lists

Plant general plans

- Civil drawings of shapes and loads

- Implementation plans and sections

Piping isometrics

- Piping isometrics drawings

Supports manufacturing plans

- Manufacturing plans for racks and supports of interconnecting piping

Skid manufacturing drawings and civil requirement drawings

- Piping assembly drawings

- Civil requirement drawing of shapes and loads

- General interconnection piping drawings

Piping isometrics

- Piping isometrics drawings

Supports manufacturing plans

- Manufacturing plans for racks and supports of interconnecting piping

Documentation for procurement and manufacturing?

Thorough.

A complete, comprehensive, and coordinated project, in which 34 official documents were submitted, including more than 800 technical drawings and 50 bills of materials. This reflects not only the complexity of the system but also the rigor and efficiency of our team. A comprehensive solution, documented down to the last detail, guarantees quality, traceability, and successful execution.

¿Errors?

As few as possible.

Two-phase quality control with 162 verification points.

We applied our proprietary quality control system to the engineering work performed for Ostroleka. In this specific case, we used two successive phases to filter out potential errors: first the 3D BIM model and then all drawings and documentation, reviewing a total of 162 points to avoid costs and delays in manufacturing, which are always more costly to correct.

1. Detailed review and validation of the design of each of the skids.

2. Quality control of documentation for purchasing and manufacturing.

The result is an error-free 3D BIM model, saving time and additional costs in manufacturing and construction.

We don't know everything.

But if you’re looking for peace of mind when designing your next (or current) water treatment plant using a 3D model and BIM methodology, maybe we can help.

Call now or send a WhatsApp to Federico Clara at (+34) 618 238 947.

Or send us the attached form and we’ll get back to you as soon as possible